Alaabta

Platelet Calcined Alumina Powder

Plate Calcined Alumina polishing budada waxay ka samaysan tahay budo alumina warshadeed oo tayo sare leh sida walxo ceeriin ah, waxaana lagu farsameeyaa hab wax soo saar gaar ah.Qaabka kristaalka ah ee budada alumina ee la soo saaray ayaa ah laba geesood oo siman sida qaab qaabaysan, sidaa darteed waxa loo yaqaan Platelet Alumina ama Tabular Alumina.

Platelet Alumina waa budo aluminium ah oo tayo sare leh, oo ka kooban kareem qaabeysan oo saxan ah oo Al2O3 leh oo nadiif ah oo ka badan 99.0%.Waxay leedahay sifooyin kulaylka u adkaysta oo aad u fiican iyo sidoo kale inay tahay mid kiimiko ahaan aan shaqaynayn, oo aanay daxaloobayn aashito ama alkaline midkood.Maaddaama qaybinta cabbirka walxaha Platelet Alumina si adag loo xakameeyo, waxay soo saari kartaa dusha dhabta ah ee aad u fiican, taasoo siinaysa waxtar sare leh sida xoqid.Isticmaalka badan ee baaxadda leh, Platelet Alumina waa budo xoqan oo awood u leh inay qabato hawlo badan.

budada aluminium ee tabular

budada aluminium ee tabular

Tilmaamaha caadiga ah ee Cabbirka Qaybaha

| Qayb | Qaybinta Walxaha (µm) | |||

| Qaybka ugu badan | Cabbirka walxaha | Cabbirka walxaha | Cabbirka walxaha | |

| 45 | 82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8± 1.8 |

| 40 | 77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | 64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | 50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | 40.3 | 26.3± 1.9 | 17.4± 1.3 | 10.4± 0.8 |

| 20 | 32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00±0.80 |

| 15 | 25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30±0.50 |

| 12 | 20.2 | 12.8± 1.0 | 8.20±0.60 | 4.90±0.40 |

| 9 | 16.0 | 9.70±0.80 | 6.40±0.50 | 3.60±0.30 |

| 5 | 12.7 | 7.20±0.60 | 4.70±0.40 | 2.80±0.25 |

| 3 | 10.1 | 5.20±0.40 | 3.10±0.30 | 1.80± 0.30 |

Heerka Tayada

| Nooca alaabta | Cufis-jiidad gaar ah | ||||

| Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| 3µm-45µm | 3.90 | 99.0 | 00.20 | 0.10 | 1.00

|

Faa'iidooyinka Alumina Powder

1. Is barbar dhig budada kale ee tabular, budada alumina ee tabular waxay leedahay sifooyin isku dhafan oo aad u fiican.Sida barta dhalaalka sare, qallafsanaanta xooggan, xoogga farsamada sare, caabbinta xirashada wanaagsan, caabbinta kiimikada, caabbinta oksaydhka iyo caabbinta kulaylka iwm.

2. Qaabka xaashida fidsan waxay ka dhigaysa is jiid jiidka mid weyn, waxay wanaajisaa xawaaraha wax lagu shiido iyo hufnaanta, tani waxay yarayn kartaa tirada mishiinnada wax shiida, wakhtiga foosha iyo wax shiida.

3. Qaabka xaashida fidsan waxa uu ka dhigayaa shayga in aan si fudud loo xoqin, heerka badeecadaha u qalma waxa uu kordhin karaa 10%-15%.Tusaale ahaan, qiyaasta waferka silikon ee semiconductor u qalma wuxuu gaari karaa 96% ama ka badan.

4. Waxay leedahay saamaynta double ee nano iyo budada micro, dhaqdhaqaaqa dusha sare waa mid dhexdhexaad ah, ma aha oo kaliya si wax ku ool ah isku darka kooxaha kale ee firfircoon, laakiin sidoo kale ma fududa in ay agglomerate iyo fududeeyo kala firidhsan wax ku ool ah.

5. Leh ku dheggan wanaagsan, saamayn gaashaamo oo muhiim ah iyo karti uu ku muujiyo iftiinka.

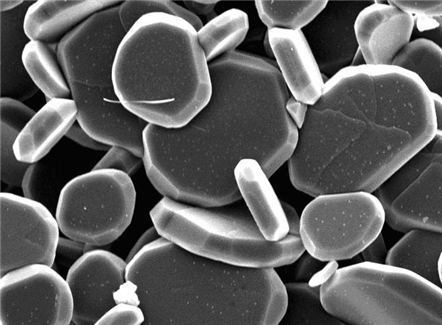

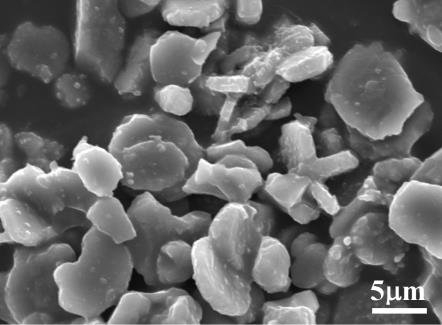

6. Budada aluminiumka ah ee tabular waxay ku dhowdahay hufan, aan midab lahayn, waxayna leedahay meel siman oo siman.crystals-ka si fiican u-cystallized waa hexagons joogto ah.

7. Budada alumina ee tabular waxaa laga dhigi karaa budo dhalaalaysa oo aad u fiican.

1. Warshadaha elektiroonigga ah: shiida iyo turxaan bixinta semiconductor monocrystalline silicon wafers, kiristaalo quartz quartz, semiconductors ka kooban (crystalline gallium, phosphating nano).

2. Warshadaha galaaska: shiida iyo habaynta ee crystal, quartz galaas, kinescope galaas galaas screen, muraayad indhaha, muraayada dareere crystal (LCD) substrate galaas, iyo crystal quartz.

3. Warshadaha dahaarka: dahaarka gaarka ah iyo buuxinta buufinta balaasmaha.

4. Warshadaha farsamaynta birta iyo dhoobada: alaabta dhoobada saxda ah, alaabta ceeriinka ah ee sintered, lakabyada heerkul sare ee heerkul sare, iwm.

Weydiintaada

Haddii aad wax su'aalo ah qabtid. Fadlan xor ayaad u tahay inaad nala soo xiriirto.