Alaabta

Dheeman synthetic Polishing Micro Powder

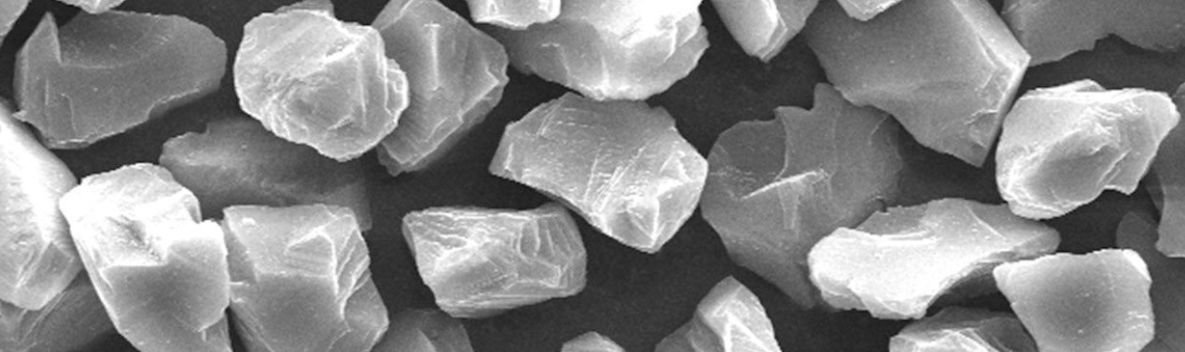

Monocrystalline Diamond Powder

Monocrystalline Diamond Powder waxaa laga soo saaraa dheeman macmal ah oo hal crystal ah miro abrasive ah iyadoo loo marayo habka cadaadiska joogtada ah, kaas oo la jajabiyey lana qaabeeyey iyadoo la isticmaalayo hab gaar ah oo loogu talagalay walxaha aadka u adag. Qaybaheeda waxa ay xajistaa sifaha kiristaalka ah ee hal dheeman.

| Tilmaamid | D50 (μm) | Tilmaamid | D50 (μm) |

| 0-0.05 | 0.05 | 5-10 | 6.5 |

| 0-0.08 | 0.08 | 6-12 | 8.5 |

| 0-0.1 | 0.1 | 8-12 | 10 |

| 0-0.25 | 0.2 | 8-16 | 12 |

| 0-0.5 | 0.3 | 10-20 | 15 |

| 0-1 | 0.5 | 15-25 | 18 |

| 0.5-1.5 | 0.8 | 20-30 | 22 |

| 0-2 | 1 | 20-40 | 26 |

| 1-2 | 1.4 | 30-40 | 30 |

| 1-3 | 1.8 | 40-60 | 40 |

| 2-4 | 2.5 | 50-70 | 50 |

| 3-6 | 3.5 | 60-80 | 60 |

| 4-8 | 5 |

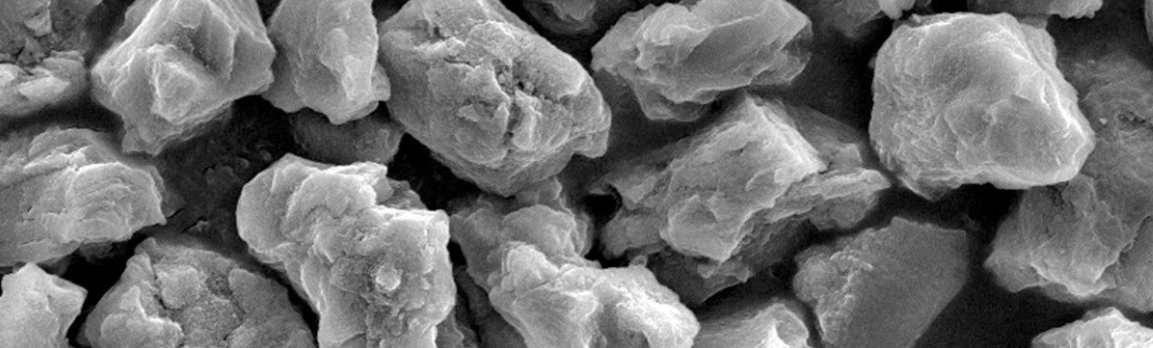

Powder Dheeman Polycrystalline

Budada dheemanka ee Polycrystalline waa micron iyo qaybo ka mid ah qaybaha polycrystalline-ka hoose oo ka kooban miro dheeman ah oo leh dhexroor 5 ~ 10nm oo ku xidhan curaarta aan saturated lahayn. Guduhu waa isotropic mana laha diyaarado kala goysa. Leh adayg sare. Iyada oo ay ugu wacan tahay sifooyinkeeda qaabdhismeed ee gaarka ah, waxaa badanaa loo isticmaalaa shiididda iyo nadiifinta alaabta semiconductor, ceramics sax ah, iwm.

Cabbirrada la heli karo ee budada yar-yar ee dheeman waa sida soo socota:

Astaamaha Alaabta

-Guud ahaan gebi ahaanba waa laga saaray

-PSD cidhiidhi ah

-Nadiifnaanta dusha sare waxay gaari kartaa heerka ppm

- Kala firdhinta muuqata

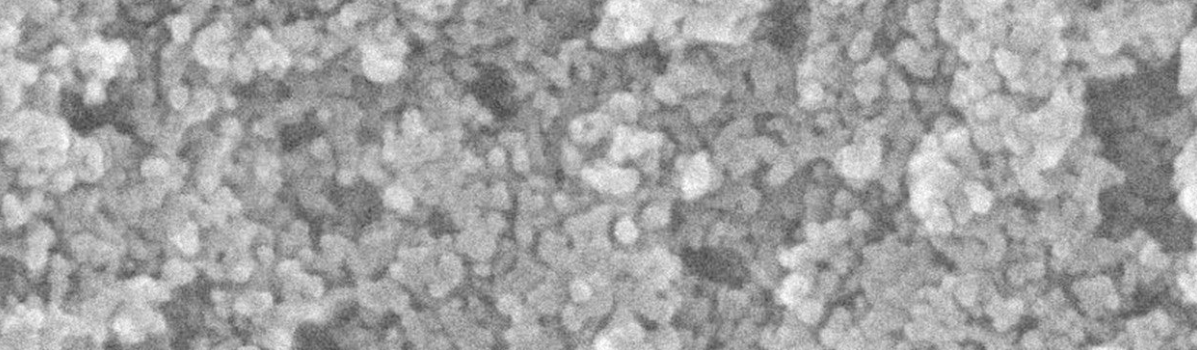

Nano Dheeman Powder

Budada dheemanka Nano waxaa lagu sameeyay kiristaalo yaryar oo ka hooseeya 20 nanometer, xaalada qarxinta gaarka ah waxay soo saartaa dheeman qaabaysan oo leh koox hodan ah oo dusha sare ah, aagga dusha sare ee gaarka ah waxaa lagu kordhiyaa hal amar oo cabbir ah marka loo eego dheemanka monocrystalline. Alaabtani ma aha oo kaliya inay leedahay qallafsanaanta aadka u fiican iyo sifooyinka dheeman, laakiin sidoo kale waxay leedahay sifooyinka cusub ee alaabta nanofunctional.

| Cabbirrada | ND50 | ND80 | ND100 | ND120 | ND150 | ND200 | ND300 | ND500 | ND800 |

| D50(nm) | 45-55 | 75-85 | 90-110 | 110-130 | 140-160 | 180-220 | 280-320 | 450-550 | 750-850 |

Astaamaha

Monocrystalline Dheeman Powder Codsiga

1. Ku habboon fiilooyin dheeman ah oo kala duwan oo sax ah oo kala duwan, giraangiraha dheemanka elektaroonigga ah ee elektiroonigga ah, Goynta SiC crystal, mindiyo, daab miinshaar aad u khafiif ah, iwm.

2. Ku habboon go'yaal isku dhafan dheeman, polycrystalline dheeman iyo alaabta bond bond, alaabta bond dhoobada, alaabta dheeman koronto, iwm.

3. Ku habboon qalabka dheemanka ah ee elektiroonigga ah, giraangiraha shiida, iwm. oo si gaar ah loogu isticmaalo farsamaynta walxaha adag iyo kuwa jilicsan.

4. Ku haboon shiidida saxda ah iyo nadiifinta dhagaxyada saxda ah ee dhamaadka-dhamaadka ah, lenses, metallographic consumables, LCD panels, LCD galaas, sapphire, xaashida quartz, LED substrates sapphire, muraayadda LCD, alaabta dhoobada, iwm.

Codsiyada budada dheeman ee polycrystalline

1. khafiif ah oo dhalaalaysa marawaxadaha semiconductor, sida waferka SiC iyo sapphire

2.Surface polishing ee alaabta dhoobada kala duwan

3.Surface polishing ee alaabta biraha, sida birta ahama, daawaha aluminium iyo wixii la mid ah

Codsiyada budada Nano dheeman

1. Daal aad u fiican. Qallafsanaanta dusha sare ee alaabta shaqada ee la sifeeyay waxay gaari kartaa heerka angstrom iyada oo aan la xoqin, taas oo qancin karta dalabka codsiyada nadiifinta ee ugu adag.

2. Dheemanka Nano waxaa loo isticmaali karaa sida saliidda lagu daro. Xumaanta simbiriirixidda ayaa loo beddeli doonaa is-jiidjiid, taas oo yarayn karta isku-xidhka isku-xidhka oo si weyn u wanaajinaya waxqabadka isku-dhacyada iyo sidoo kale sii dheerayn kara nolosha adeegga.

3. Daahinta isku dhafan iyo buufinta dusha sare ee workpieces kala duwan, kor u adkaysiga xidhashada, iska caabin daxalka, adkaanta saamaynta iyo adkaanta of workpieces '.

4. Sida caagga iyo caagadaha lagu daro, dheeman nano si weyn ayuu u wanaajin karaa caabbinta xirashada, caabbinta daloolinta, hantida jilicsan iyo sidoo kale hoos u dhigida habka gabowga.

5. Nano dheeman nadiif ah oo nadiif ah ma keeni doonto diidmo bayooloji, Dhanka kale waxaa si weyn loogu isticmaali karaa goobaha caafimaadka, noolaha iyo qurxinta sababtoo ah aagga sare ee gaarka ah ee weyn, awoodda adsorption xooggan.

Weydiintaada

Haddii aad wax su'aalo ah qabtid. Fadlan xor ayaad u tahay inaad nala soo xiriirto.