Codsiga α-alumina ee cusubaluminium ceramics

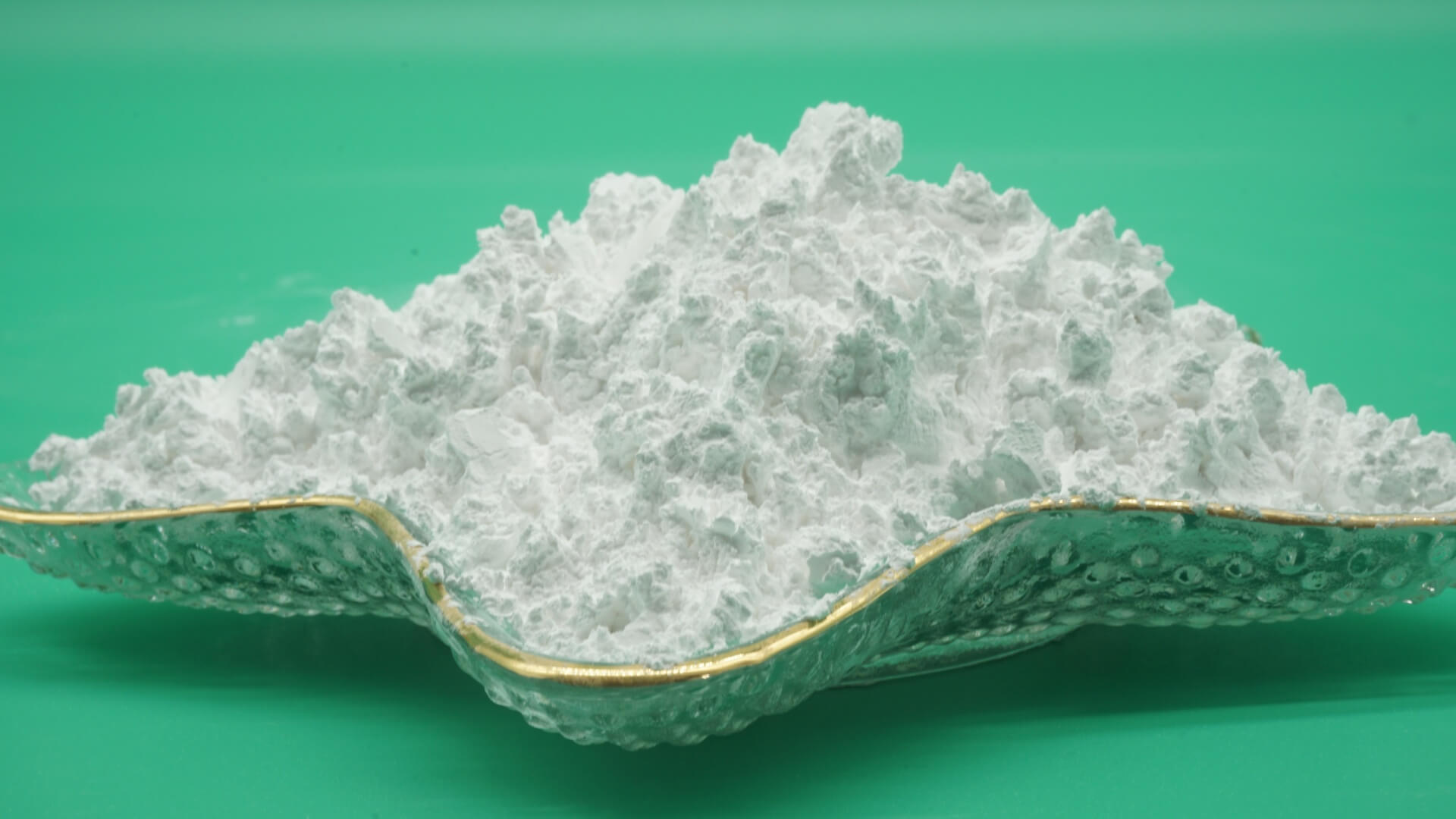

Inkasta oo ay jiraan noocyo badan oo ah alaabta dhoobada cusub, waxay qiyaas ahaan loo qaybin karaa saddex qaybood iyadoo loo eegayo shaqadooda iyo adeegsigooda: dhoobada shaqaynaysa (sidoo kale loo yaqaan dhoobada elektaroonigga ah), dhoobada qaab dhismeedka (oo sidoo kale loo yaqaan ceramics injineernimada) iyo bioceramics. Marka loo eego qaybaha kala duwan ee alaabta ceeriin ee la isticmaalo, waxaa loo qaybin karaa ceramics oxide, ceramics nitride, ceramics boride, ceramics carbide iyo ceramics biraha. Waxaa ka mid ah, ceramics alumina waa mid aad muhiim u ah, iyo alaabteeda ceeriin waa budada α-alumina ee tilmaamo kala duwan.

α-alumina waxaa si weyn loogu isticmaalaa soo saarista noocyo kala duwan oo alaab dhoobo ah oo cusub sababtoo ah xooggeeda sare, adkaanta sare, caabbinta heerkulka sare, xirashada caabbinta iyo sifooyin kale oo aad u fiican. Ma aha oo kaliya budada ceramics alumina horumarsan sida substrates circuit isku dhafan, dhagaxyo macmal ah, qalab goynta, lafaha macmal ah, iwm, laakiin sidoo kale waxaa loo isticmaali karaa sida side fosfoor, qalabka refractory horumarsan, alaabta shiidi gaar ah, iwm Iyada oo horumarinta sayniska casriga ah iyo tignoolajiyada, goobta codsiga ee α-alumina si degdeg ah u ballaarinaya, iyo rajooyinka suuqa waa mid aad u ballaaran.

Codsiga α-alumina ee dhoobada shaqaynaysa

dhoobada shaqaynaysatixraac dhoobada horumarsan ee isticmaala korontadooda, magnetic, acoustic, indhaha, kulaylka iyo waxyaabaha kale ama saameyntooda isku xidhka si loo gaaro hawl gaar ah. Waxay leeyihiin sifooyin koronto oo badan sida dahaarka, dielectric, piezoelectric, thermoelectric, semiconductor, conductivity ion iyo superconductivity, sidaas darteed waxay leeyihiin hawlo badan iyo codsiyo aad u ballaaran. Waqtigan xaadirka ah, kuwa ugu muhiimsan ee loo isticmaalo isticmaalka wax ku oolka ah ee baaxadda weyn ayaa ah dhoobada dhoobada ah ee isku-dhafka ah ee isku-dhafka ah ee isku-dhafka ah iyo baakadaha, dhoobada gawaarida gawaarida, ceramics capacitor dielectric oo si ballaaran loogu isticmaalo telefishinada iyo duubayaasha fiidiyowga, ceramics piezoelectric leh isticmaalka badan iyo ceramics xasaasi ah oo loogu talagalay dareemayaasha kala duwan. Intaa waxaa dheer, waxaa sidoo kale loo isticmaalaa nalalka soodhiyamka cadaadiska sarreeya ee tuubooyinka iftiinka soo saara.

1. dhoobada dahaarka ah ee spark

dhoobada dahaarka leh ee Spark plug ayaa hadda ah codsiga kaliya ee ugu weyn ee dhoobada matoorada. Sababtoo ah alumina waxay leedahay dahaar koronto oo heer sare ah, xoog farsamo oo sarreeya, iska caabin cadaadis sare ah iyo caabbinta shoogga kulaylka, alumina dahaarka dhinbiilayaasha ayaa si weyn looga isticmaalaa adduunka. Shuruudaha α-alumina ee dhinbiilayaashu waa kuwa caadiga ah ee hooseeya-sodium α-alumina micropowders, kaas oo maadada sodium oxide ay tahay ≤0.05% celceliska cabbirka walxaha waa 325 mesh.

2. Substrates wareegyada isku dhafan iyo alaabta baakadaha

Ceramics loo isticmaalo sida alaabta substrate iyo alaabta baakadaha ayaa ka sarreeya balaastikada dhinacyada soo socda: caabbinta dahaarka sare, caabbinta daxalka kiimikada sare, shaabadeynta sare, ka hortagga galinta qoyaanka, falcelin la'aan, iyo wax wasakh ah oo aan lahayn silikoon semiconductor ultra saafi ah. Qalabka α-alumina ee looga baahan yahay substrates-ka isku-dhafan ee isku-dhafka ah iyo alaabta baakadaha waa: isugeynta ballaarinta kulaylka 7.0 × 10-6 / ℃, kuleylka kuleylka 20-30W / K · m (heerkulka qolka), dielectric joogto ah 9-12 (IMHz), dielectric khasaaro 3 ~ 10-4 (IMHz), mugga-20-10%

Iyada oo la adeegsanayo waxqabadka sare iyo is dhexgalka sare ee wareegyada isku dhafan, shuruudo adag ayaa loo soo bandhigay substrates iyo alaabta baakadaha:

Marka jiilka kulaylka ee chip uu kordho, heerkulka kulaylka sare ayaa loo baahan yahay.

Iyada oo xawaaraha sare ee curiyaha xisaabinta, joogto ah dielectric hoose ayaa loo baahan yahay.

Isku xidhka balaadhinta kulaylka ayaa looga baahan yahay inuu u dhawaado silikoon. Tani waxay dhigaysaa shuruudo sare oo ku saabsan α-alumina, taas oo ah, waxay ku koraan jihada nadiifnimada sare iyo ganaaxa.

3. Cadaadis sare oo soodhiyam iftiin-bixiya

dhoobada Fiicanoo ka samaysan saafiga sare ee ultrafine alumina sida alaabta ceeriin waxay leeyihiin sifooyinka caabbinta heerkulka sare, caabbinta daxalka, dahaarka wanaagsan, xoogga sare, iwm, waana qalab dhoobo ah oo aad u fiican. Polycrystalline hufan oo ka samaysan aluminium-nadiif sare leh oo leh qadar yar oo ah magnesium oxide, iridium oxide ama waxyaabaha lagu daro iridium oxide, oo ay sameeyeen jawiga jawiga iyo cadaadiska kulul, waxay u adkeysan kartaa daxalka uumiga soodhiyamka heerkulka sare waxaana loo isticmaali karaa sida nalalka soodhiyamka-cadaadiska sare leh oo leh iftiin sare.

Codsiga α-alumina ee dhoobada qaab dhismeedka

Maaddaama maaddooyinka biomedical-ka ah ee aan organic ahayn, alaabta bioceramic ma laha waxyeellooyin sun ah marka la barbar dhigo qalabka birta iyo walxaha polymer, waxayna leeyihiin biocompatibility wanaagsan iyo iska caabin daxalka leh unugyada noolaha. Waxaa aad loo qiimeeyay dadku. Cilmi baarista iyo adeegsiga kiliinikada ee agabka bioceramic waxay ka soo baxeen beddelaad waqti-gaaban iyo buuxin ilaa la geliyo joogto ah oo adag, iyo walxaha noolaha ah ee aan firfircoonayn ilaa agab noole firfircoon iyo walxo isku dhafan oo isku dhafan.

Sanadihii la soo dhaafay, daloolaluminium ceramicsayaa loo isticmaalay in lagu sameeyo kala-goysyada lafaha macmalka ah, kala-goysyada jilibka macmalka ah, madax femoral macmal ah, lafo kale oo macmal ah, xididdada iliga macmalka ah, boolal hagaajinta lafaha, iyo hagaajinta corneal ay sabab u tahay caabbinta daxalka kiimikaad, xidho caabbinta, heerkul wanaagsan oo deggan xasilloon, iyo guryaha kulaylka. Habka lagu xakameynayo cabbirka daloolka inta lagu jiro diyaarinta dhoobada alumina ee daloola waa in la isku daro walxaha alumina ee cabbirrada kala duwan, xumbo impregnate, iyo buufin qallaji qaybaha. Taarikada aluminiumku sidoo kale waa la anodized si ay u soo saaraan jihada nano-cabbirka microporous-daloolada nooca channel.