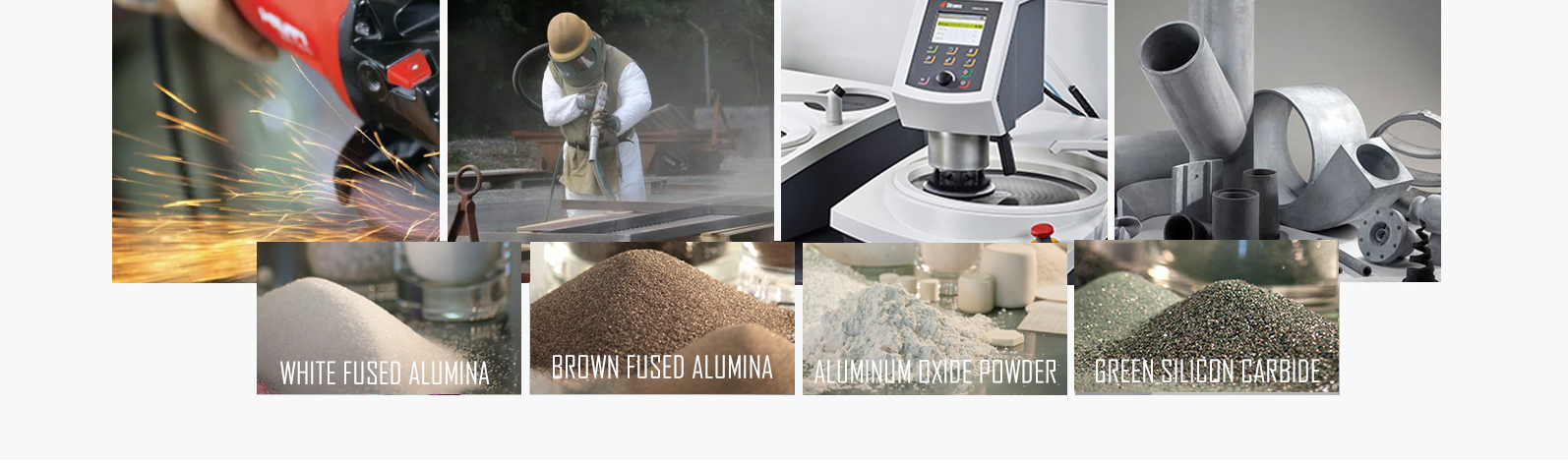

Alaabta

F12-F220 Cadaan la isku daray Alumina Oxide Grits

Aluminiin cad oo isku dhafan

Alumina cad oo isku darsan waxay ka samaysan tahay budada alumina ee sodium-hoose ee nadiifka ah iyadoo lagu dhalaalinayo heerkulka sare, qaboojinta crystallization, ka dibna la burburiyo. Gawaarida alumina ee isku dhafan ee cad ayaa si adag loo xakameynayaa si loo ilaaliyo qaybinta cabbirka hadhuudhka iyo muuqaalka joogtada ah.

Guryaha aluminiumka ah ee la isku daray ee Whiet

Caddaan, α crystal in ka badan 99%, daahir sare, qallafsanaan sare, iyo adayg sare, xoog goyn xoog leh, degganaansho kiimikaad xoog leh, iyo dahaar adag.

| Mohs adag | 9 |

| Cufnaanta weyn | 1.75-1.95g/cm3 |

| Cuf-jiid gaar ah | 3.95g/cm3 |

| Cufnaanta mugga | 3.6 |

| shahaado dhalaalaysa | 2250 ℃ |

| Shahaadada dib-u-celinta | 2000℃ |

| Loo isticmaalo dib-u-celinta, la tuuri karo | |||||

| Guryaha | 0-1 1-3 3-5m/m | F100 F200 F325 | |||

| Qiimaha Dammaanadda | Qiimaha caadiga ah | Qiimaha Dammaanadda | Qiimaha caadiga ah | ||

| Halabuurka Kiimikada | Al2O3 | ≥99.1 | 99.5 | ≥98.5 | 99 |

| SiO2 | ≤0.4 | 0.06 | ≤0.30 | 0.08 | |

| Fe2O3 | ≤0.2 | 0.04 | ≤0.20 | 0.1 | |

| Na2O | ≤0.4 | 0.3 | ≤0.40 | 0.35 | |

| Waxa loo isticmaalaa nabarrada, qarxinta, shiididda | |||

| Guryaha | Badar | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Qiimaha Dammaanadda | Qiimaha caadiga ah | ||

| Halabuurka Kiimikada | Al2O3 | ≥99.1 | 99.5 |

| SiO2 | ≤0.2 | 0.04 | |

| Fe2O3 | ≤0.2 | 0.03 | |

| Na2O | ≤0.30 | 0.2 | |

| Waxaa loo isticmaalaa xoqida, laabashada, polishing | ||||

| Guryaha | budada yar yar | |||

| "W" | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| "FEPA" | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

| "JIS" | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 10000# 6000# 10000 | |||

| Qiimaha Dammaanadda | Qiimaha caadiga ah | |||

| Halabuurka Kiimikada | Al2O3 | ≥99.1 | 99.3 | |

| SiO2 | ≤0.4 | 0.08 | ||

| Fe2O3 | ≤0.2 | 0.03 | ||

| Na2O | ≤0.4 | 0.25 | ||

1. Carro-qarxinta, turxaan bixinta iyo shiididda biraha iyo dhalooyinka.

2. Buuxinta rinjiga, dahaarka u adkaysta, dhoobada, iyo dhalaalka.

3. Samaynta dhagaxa saliidda, dhagaxa wax lagu shiido, giraangiraha shiida, warqad ciid iyo marada emery.

4.Production ee xuubka filter dhoobada, tuubooyinka dhoobada, taarikada dhoobada.

5.Wax soo saarka dareere dhalaalaysa, shamac adag iyo shamac dareere ah.

6.Isticmaalka dabaqa u adkaysta.

7. Advanced shiidi iyo polishing of kiristaalo piezoelectric, semiconductors, ahama, aluminium iyo biraha kale iyo kuwa aan biraha.

8.Specifications iyo halabuurka

Weydiintaada

Haddii aad wax su'aalo ah qabtid. Fadlan xor ayaad u tahay inaad nala soo xiriirto.